Best Custom Paper Bag Manufacturer

Laku Prosper Edge

Laku Prosper Edge stands out as the leading custom paper bag manufacturer by combining innovation with sustainability. With state-of-the-art manufacturing techniques, they offer high-quality, durable paper bags tailored to meet diverse customer needs. From bespoke designs to eco-friendly materials, Laku Prosper Edge ensures that each product aligns with environmental standards while maintaining aesthetic appeal, functionality, and long-lasting durability.

Our commitment to excellence is reflected in its unmatched customer service, precision in fulfilling bulk orders, and attention to detail. We are continuously enhancing our production processes and embracing cutting-edge technology, Laku Prosper Edge provides personalized packaging solutions. This dedication makes us a preferred choice for businesses seeking quality and sustainability.

WHY CHOOSE US AS A CUSTOM PAPER BAG MANUFACTURER

- High-Quality, Custom Packaging: Laku Prosper Edge specializes in creating custom-made paper bag solutions tailored to specific brand needs.

- Sustainability Focus: We utilize eco-friendly materials, ensuring both durability and a premium feel while adhering to environmental standards.

- Tailored Designs and Sizes: Our skilled team can produce paper bags with unique designs and specific sizes to meet exact customer specifications.

- Timely Delivery and Excellent Service: Laku Prosper Edge is committed to prompt delivery and provides seamless customer support throughout the production process.

- Reliable Partnership: We offer a combination of creativity, sustainability, and reliability, making us a leading choice for packaging needs.

OUR RANGE OF PRODUCT

Laku Prosper Edge offers an extensive range of premium custom paper bags designed to meet diverse packaging needs. From elegant retail bags to sturdy food packaging, our products cater to various industries, including fashion, food, and cosmetics. Crafted with eco-friendly materials, our bags are fully customizable, offering unique designs, sizes, and finishes to perfectly represent your brand while ensuring both style and sustainability in every product.

Paper Bag

Manufacturer

- SOS Paper Bag

- Printed Paper Bag

- Brown Paper Bag

- White Paper Bag

V Bottom Paper Bag

- Twisted/Flat Handle Paper Bag

Bubble Wrap Manufacturer

- Honeycomb Bubble Wrap

- Paper Bubble Wrap

production facility

Laku Prosper’s Edges Production Facility is a state-of-the-art manufacturing plant dedicated to high-quality production processes, including specialized expertise as a Custom Paper Bag Manufacturer. Equipped with advanced technology and skilled personnel, the facility produces precision-engineered components and custom paper bags tailored to diverse industry needs. Committed to sustainability, the facility ensures efficient resource utilization while maintaining top-tier standards. Its modern infrastructure supports both large-scale production and flexible customization, making it a key player in the global market.

Paper Bubble Wrap

Rolls Per Month

Paper Bag

Per Month

- Located in a strategic area for easy distribution and logistics.Utilizes cutting-edge machinery and automation for efficiency.

- Implements stringent quality control measures to ensure product consistency. Focuses on innovation with continuous research and development efforts.

- Operates with a strong commitment to sustainability and eco-friendly practices. Provides custom solutions tailored to client specifications and industry needs.

- Offers scalable production capabilities to meet both small and large orders. Employs highly trained professionals dedicated to excellence in manufacturing. Prioritizes safety, ensuring a secure working environment for employees.

INDUSTRY EXPERTISE IN MANUFACTURING

Laku Prosper’s expertise in manufacturing custom paper bags spans years of innovation and commitment to high-quality production. Laku Prosper Edge has established itself as a leader in the paper bag industry by leveraging advanced machinery and eco-friendly materials. With a focus on precision, durability, and functionality, our production process ensures that each bag meets international standards for strength and reliability. By utilizing state-of-the-art technology, Laku Prosper Edge crafts paper bags in various sizes and designs, catering to a diverse range of industries, from retail and food service to fashion and packaging.

Our deep understanding of market trends and consumer needs allows us to provide customized solutions, offering eco-conscious alternatives to plastic bags. We focus on sustainability extends beyond the product itself, as we actively seek to reduce environmental impact through efficient manufacturing processes. With an unwavering commitment to quality, customer satisfaction and sustainable practices, Laku Prosper Edge remains a trusted name among giant custom paper bag manufacturers consistently delivering exceptional products that meet the evolving needs of businesses worldwide.

ORDER PROCESS

Understanding Your Requirement

- Product Definition: Specify paper bag or honeycomb wrap dimensions and quantities.

- Material Preferences: Choose paper types, eco-friendly options, and wrap thickness.

- Customization Details: Indicate desired prints, logos, or branding elements.

- Strength & Durability: Define requirements for load capacity and protection.

- Delivery Expectations: Discuss timelines and shipping preferences.

- Budget Considerations: Align material and design choices with your financial parameters.

- Sample Requests: Request samples to ensure material quality.

Paper Selection & Specification

- Requirement Gathering: Laku Prosper Edge begins by understanding your precise bag & wrap needs.

- Material Consultation: Experts guide you in choosing optimal paper types.

- Eco-Friendly Options: Sustainable paper and honeycomb choices are available.

- Texture & Finish: Matte, glossy, and custom finishes are offered.

- Weight & Thickness: Precise paper weight and thickness are specified.

- Customization: Tailored materials for your unique packaging needs.

- Final Approval: Your approval confirms the chosen paper specifications.

Designing & Approval

- Consultation: We discuss your specific paper bag and honeycomb wrap needs.

- Design Creation: Our team crafts custom designs or adapts your existing artwork.

- Material Selection: We present various paper and honeycomb options.

- Digital Proof: You receive a digital proof for review and adjustments.

- Feedback & Revisions: We incorporate your feedback for design refinement.

- Final Approval: Your approval is required before production begins.

- Laku Prosper Edge Guarantee: Ensuring your design meets your expectations.

Production & Packaging

- Production Initiation: Following design approval and material selection, we enter the production phase.

- Advanced Manufacturing: Paper bags are produced using our modern, high-efficiency machinery.

- Rigorous Quality Control: Comprehensive quality checks are performed at each production step, guaranteeing adherence to your exact specifications.

- Precise Quantity: We ensure the correct bag quantity is produced.

- Careful Packaging: Packaging is meticulously handled to prevent any transit damage.

- Custom Packing: bags are packed based on your specific requested packaging configurations.

Product Shipping

- Production Finished: Products are prepared for shipment.

- Logistics Management: Timely delivery is handled by our logistics team.

- Shipping Choices: We offer diverse shipping options for your needs.

- Dispatch Notification: Tracking information provided upon order dispatch.

- Domestic/International: Clients select from domestic or international shipping.

- Bulk/Retail Delivery: Options include warehouse or retail outlet shipments.

- Packaging Integrity: Packaging protects product condition during transit.

Understanding Your Requirement

- Product Definition: Specify paper bag or honeycomb wrap dimensions and quantities.

- Material Preferences: Choose paper types, eco-friendly options, and wrap thickness.

- Customization Details: Indicate desired prints, logos, or branding elements.

- Strength & Durability: Define requirements for load capacity and protection.

- Delivery Expectations: Discuss timelines and shipping preferences.

- Budget Considerations: Align material and design choices with your financial parameters.

- Sample Requests: Request samples to ensure material quality.

Paper Selection & Specification

- Requirement Gathering: Laku Prosper Edge begins by understanding your precise bag & wrap needs.

- Material Consultation: Experts guide you in choosing optimal paper types.

- Eco-Friendly Options: Sustainable paper and honeycomb choices are available.

- Texture & Finish: Matte, glossy, and custom finishes are offered.

- Weight & Thickness: Precise paper weight and thickness are specified.

- Customization: Tailored materials for your unique packaging needs.

- Final Approval: Your approval confirms the chosen paper specifications.

Designing & Approval

- Consultation: We discuss your specific paper bag and honeycomb wrap needs.

- Design Creation: Our team crafts custom designs or adapts your existing artwork.

- Material Selection: We present various paper and honeycomb options.

- Digital Proof: You receive a digital proof for review and adjustments.

- Feedback & Revisions: We incorporate your feedback for design refinement.

- Final Approval: Your approval is required before production begins.

- Laku Prosper Edge Guarantee: Ensuring your design meets your expectations.

Production & Packaging

- Production Initiation: Following design approval and material selection, we enter the production phase.

- Advanced Manufacturing: Paper bags are produced using our modern, high-efficiency machinery.

- Rigorous Quality Control: Comprehensive quality checks are performed at each production step, guaranteeing adherence to your exact specifications.

- Precise Quantity: We ensure the correct bag quantity is produced.

- Careful Packaging: Packaging is meticulously handled to prevent any transit damage.

- Custom Packing: bags are packed based on your specific requested packaging configurations.

Product Shipping

- Production Finished: Products are prepared for shipment.

- Logistics Management: Timely delivery is handled by our logistics team.

- Shipping Choices: We offer diverse shipping options for your needs.

- Dispatch Notification: Tracking information provided upon order dispatch.

- Domestic/International: Clients select from domestic or international shipping.

- Bulk/Retail Delivery: Options include warehouse or retail outlet shipments.

- Packaging Integrity: Packaging protects product condition during transit.

1. Product Research

- Market Analysis: This step involves studying the target market to understand consumer needs, preferences, and trends. It includes competitor analysis to identify gaps and opportunities in the market.

- Formula Development: Based on market insights, a unique product formula or design is created to meet specific consumer needs. The formulation team selects ingredients or components that will deliver the desired functionality.

2. Testing & Stability

- Performance Testing: Products are tested under different conditions to ensure they perform as intended. This can include sensory tests, durability checks, or usage trials to validate effectiveness and appeal.

- Stability Testing: The product is exposed to various environmental factors like temperature, light, and humidity to verify shelf life. Stability testing ensures that the product remains safe, effective, and visually appealing over time.

3. Packaging Selection & Branding

- Material Selection: Packaging material is chosen based on factors like durability, environmental impact, and compatibility with the product. It must protect the product and be easy for consumers to use.

- Branding Design: This involves creating an attractive design that aligns with the brand’s identity and appeals to target consumers. Elements like colours, fonts, and logos are carefully selected to enhance brand recognition.

4. Manufacturing

- Production Planning: A detailed manufacturing plan is developed, which includes timelines, equipment, and staffing needs. This ensures that resources are optimally allocated for efficient production.

- Batch Production: The product is produced in batches, following precise specifications and using automated machinery if possible to ensure consistency and reduce human error.

5. QA/QC (Quality Assurance & Quality Control)

- Quality Assurance: QA focuses on establishing systems and protocols to prevent defects. This includes setting quality standards, training employees, and monitoring processes throughout production.

- Quality Control: QC involves inspecting the product at various stages of production to ensure it meets predefined quality criteria. Samples are often tested for properties like purity, consistency, and performance.

6. Filling & Packaging

- Filling Process: The product is filled into its final container using automated filling machines to ensure accuracy and prevent contamination. This process must be done under clean, controlled conditions.

- Labelling and Sealing: After filling, containers are labelled with important information (like ingredients, expiration dates, and instructions). Seals are added to prevent tampering and to maintain freshness.

7. Dispatch of Product

- Inventory Management: Finished products are stored in inventory, where they are managed based on demand forecasts and storage requirements to maintain quality.

- Logistics & Distribution: Products are prepared for shipment, with logistics teams coordinating transport to retailers, wholesalers, or customers. Effective distribution ensures timely and safe delivery to the market.

Product Research

- Market Analysis: This step involves studying the target market to understand consumer needs, preferences, and trends. It includes competitor analysis to identify gaps and opportunities in the market.

- Formula Development: Based on market insights, a unique product formula or design is created to meet specific consumer needs. The formulation team selects ingredients or components that will deliver the desired functionality.

Testing & Stability

- Performance Testing: Products are tested under different conditions to ensure they perform as intended. This can include sensory tests, durability checks, or usage trials to validate effectiveness and appeal.

- Stability Testing: The product is exposed to various environmental factors like temperature, light, and humidity to verify shelf life. Stability testing ensures that the product remains safe, effective, and visually appealing over time.

Packaging Selection & Branding

- Material Selection: Packaging material is chosen based on factors like durability, environmental impact, and compatibility with the product. It must protect the product and be easy for consumers to use.

- Branding Design: This involves creating an attractive design that aligns with the brand’s identity and appeals to target consumers. Elements like colours, fonts, and logos are carefully selected to enhance brand recognition.

Manufacturing

- Production Planning: A detailed manufacturing plan is developed, which includes timelines, equipment, and staffing needs. This ensures that resources are optimally allocated for efficient production.

- Batch Production: The product is produced in batches, following precise specifications and using automated machinery if possible to ensure consistency and reduce human error.

QA/QC (Quality Assurance & Quality Control)

- Quality Assurance: QA focuses on establishing systems and protocols to prevent defects. This includes setting quality standards, training employees, and monitoring processes throughout production.

- Quality Control: QC involves inspecting the product at various stages of production to ensure it meets predefined quality criteria. Samples are often tested for properties like purity, consistency, and performance.

Filling & Packaging

- Filling Process: The product is filled into its final container using automated filling machines to ensure accuracy and prevent contamination. This process must be done under clean, controlled conditions.

- Labelling and Sealing: After filling, containers are labelled with important information (like ingredients, expiration dates, and instructions). Seals are added to prevent tampering and to maintain freshness.

Dispatch of Product

- Inventory Management: Finished products are stored in inventory, where they are managed based on demand forecasts and storage requirements to maintain quality.

- Logistics & Distribution: Products are prepared for shipment, with logistics teams coordinating transport to retailers, wholesalers, or customers. Effective distribution ensures timely and safe delivery to the market.

QUALITY ASSURANCE

Laku Prosper Edge, a leading Custom Paper Bag Manufacturer, prioritizes quality assurance (QA) as the cornerstone of its commitment to excellence. Our rigorous QA system ensures the highest standards of performance, safety, and durability for all paper bag products. Through meticulous testing, constant monitoring, and adherence to industry certifications, Laku Prosper Edge guarantees that every custom paper bag meets precise specifications, making it a top choice among custom bag manufacturers. Our team of experts utilizes advanced equipment to assess material quality, construction, and functionality, ensuring consistently reliable products. Each production batch undergoes a series of quality checks, including strength, load capacity, and print quality tests, simulating real-world conditions to verify performance. Laku Prosper Edge also incorporates client feedback to continually refine and improve its QA processes. With a steadfast focus on delivering perfection, Laku Prosper Edge as a Custom Paper Bag Manufacturer, maintains exceptional quality control throughout the entire production cycle.

From sourcing raw materials to final product inspection, every step is carefully monitored to ensure that each order meets both client expectations and industry standards. Our dedication to continuous improvement and attention to detail ensures that their paper bags are not only functional but also environmentally responsible.

LOGISTIC AND DISTRIBUTION

Laku Prosper Edge makes a significant impact in the realm of “Logistics and Distribution” by employing modern, efficient & easy to work strategies. We have a robust network that ensures a smooth & timely delivery of products. This minimizes delays and increases accuracy so that our consumers do not have to wait too long for brighter smiles.

- Our Proximity to Major Transport Routes

- Major National Transporters- 1 km

- Airport – 24 km

- Cargo Railway- 10 km

- Dry Port (ICD Khodiyar, Ahmedabad) – 17

- Mundra Port- 32.5 km

We have strategic partnerships with reliable distribution channels that allow us to reach even the most remote & dense areas. We guarantee that all our clients receive the right product at the right time and in perfect condition.

Your Brand's Safety is our Priority

KEY HIGHLIGHTS OF OUR FACILITY

- Laku Prosper Edge boasts a state-of-the-art manufacturing facility that adheres to stringent global quality standards. Located in a prime industrial hub, the facility is equipped with advanced technology and automated systems for the production of high-quality Paper Bags & Honeycomb bubble wrapping paper. It focuses on ensuring high efficiency, consistency, and compliance with GMP (Good Manufacturing Practices) guidelines, ensuring product safety and reliability.

- The facility also emphasizes sustainable practices, utilizing eco-friendly systems to reduce its carbon footprint. With a dedicated team and robust quality control measures, Laku Prosper Edge continuously improves its manufacturing processes, ensuring the delivery of innovative, safe, and effective Paper Bags & Honeycomb bubble wrapping paper worldwide.

Printing Facility:

A 4-Color Flexo Printing Machine is a high-performance solution for accurate, high-quality, and vibrant printing on square-bottom paper bags. Utilizing advanced flexographic technology, this machine ensures sharp images, clear text, and consistent color registration, making it ideal for branding and packaging applications.

Paper Bag Manufacturing:

The square bottom paper bag machine is ideal for businesses looking to enhance their paper bag production with perfection, speed, and high-quality output while maintaining environmental sustainability.

It can produce 200 to 300 bags per minute while maintaining the same quality from start to end.

Paper Bubble Wrap Manufacturing:

A Honeycomb Paper Wrap Making Machine is a high-performance, fully automated solution designed for producing eco-friendly, high-strength honeycomb paper wrap for sustainable packaging. With a production capacity of 500 rolls of 100 meters per day, this machine ensures efficiency, precision, and durability, making it ideal for protective wrapping applications in e-commerce, logistics, and fragile goods packaging.

Satisfied Clients

Years Of Experience

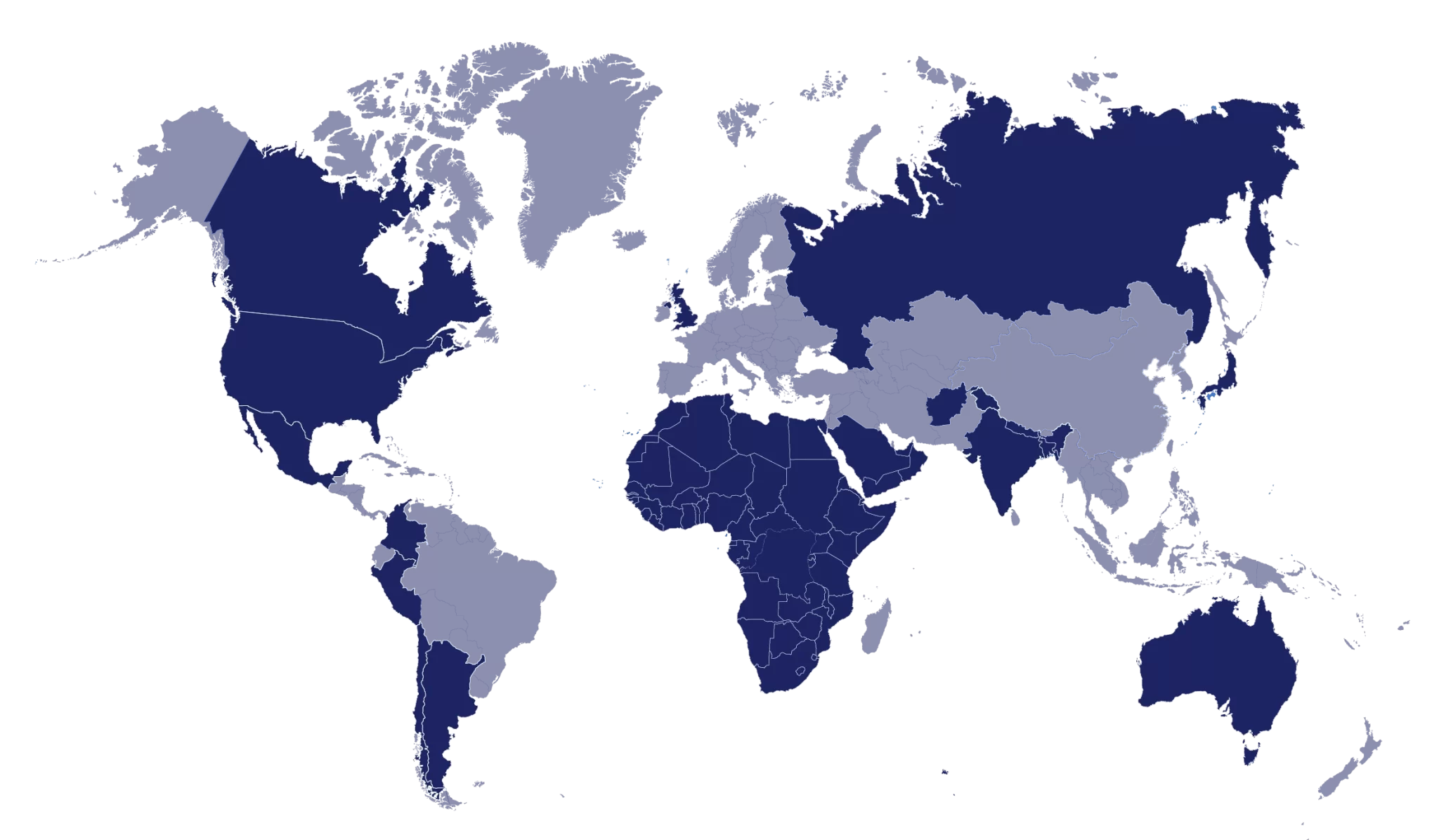

Countries Served

Global Exporters

Laku Prosper Edges has established itself as a global leader in the manufacturing sector, specializing in high-quality paper bags, including its expertise as a Custom Paper Bag Manufacturer, and precision components. With an unwavering commitment to quality, innovation, and customer satisfaction, Laku Prosper Edge built a strong reputation worldwide. Its state-of-the-art production facilities and advanced technology enable Laku Prosper Edge to produce products that meet international standards, making it a trusted name for clients across various industries.

As a global exporter, Laku Prosper Edge leverages its strategically located manufacturing plants and efficient supply chain to reach markets worldwide. We maintain a robust distribution network, ensuring timely delivery of orders while minimizing logistical challenges. Its ability to adapt to diverse market demands allows it to meet the specific requirements of customers across multiple regions.

Laku Prosper Edge’s dedication to sustainability and eco-friendly practices also sets it apart as a responsible global player. We continue to lead the industry by offering customized solutions that align with both market needs and environmental standards, reinforcing its position as a premier exporter.

CERTIFICATIONS

FAQ

1. What types of custom paper bags can Laku Prosper Edge manufacture?

We specialize in a wide range of custom paper bags, including but not limited to: SOS Paper Bag, White Paper Bag, Printed Paper Bag, Twisted Handle Paper Bags, and Flat Handle Paper Bags. We can accommodate various sizes, styles, and paper types.

2. How can I design my custom paper bags through a Laku Prosper Edge?

Designing custom paper bags with Laku Prosper Edge is a collaborative journey. You’ll start by sharing your vision, including size, material, and design preferences. Our team will guide you through material selection, printing options, and finishing touches. A sample bag ensures your satisfaction before full production, resulting in custom bags that perfectly represent your brand.

3. Are custom paper bags eco-friendly?

Yes, custom paper bags are indeed eco-friendly, especially compared to plastic alternatives. We typically use recyclable, biodegradable paper for production, reducing the environmental impact. If you want to take your eco-friendly approach further, we offer options like recycled paper, water-based inks, and non-toxic dyes. Choosing us made from sustainable materials helps reduce your carbon footprint while offering your customers an environmentally responsible product. These bags are ideal for businesses that are looking to align with sustainability practices and appeal to eco-conscious consumers.

4. What types of custom paper bags are available from a Laku Prosper Edge?

There are many types of custom paper bags to choose from, depending on your specific requirements. Common styles include flat paper bags, which are simple and cost-effective, twisted handle bags which are sturdy and versatile, die-cut handle bags which offer a sleek, modern look, and luxury folding bags which are often used for premium retail packaging. Additionally, there are bags with reinforced handles for heavier products, and some bags come with special features such as gussets for more volume or fold-over tops for secure closure. Your choice will depend on the nature of your products and the branding experience you want to create for your customers.

5. Can custom paper bags be printed in full color by a Laku Prosper Edge?

Yes, custom paper bags can be printed in full color, allowing you to showcase intricate designs, vibrant logos, and detailed graphics. We use high-quality printing techniques such as offset printing or flexographic printing, which ensure your colors come out bright and sharp. Whether you want a single-color design or a multi-color print, your custom paper bags can reflect your brand’s personality and catch the eye of customers. Full-color printing is a great option for businesses looking to make a bold impression with their packaging.

6. What is the minimum order quantity (MOQ) for custom paper bags from a Laku Prosper Edge?

The minimum order quantity (MOQ) for custom paper bags from Laku Prosper Edge varies depending on factors like bag size, paper type and printing complexity. To get a precise MOQ, it’s best to contact us directly, as we tailor our offerings to each client’s specific needs. we will provide a personalized quote based on your requirements.

7. How long does it take to produce custom paper bags through a Laku Prosper Edge?

The production time for custom paper bags at Laku Prosper Edge varies based on order size, complexity, and material choices. After design approval, expect a timeframe that includes sample creation, printing, and finishing. Laku Prosper Edge will provide a specific estimate upon order confirmation, ensuring you’re informed throughout the process. It’s important to plan and allow enough time for both production and shipping to ensure you receive your bags when you need them. If your order involves special features like embossing or foil stamping, it may take a bit longer.

8. Can I order custom paper bags in bulk from a Laku Prosper Edge?

Yes, Laku Prosper Edge specializes in bulk orders for custom paper bags. They cater to businesses needing large quantities, offering tailored solutions for various needs. Contact Us with your specific requirements, including bag size, material, design and quantity for a personalized quote and efficient production.

9. What materials are used to make custom paper bags by a Laku Prosper Edge?

Custom paper bags can be made from a variety of materials, each chosen for its durability, aesthetic, and eco-friendly properties. The most common materials used by us are kraft paper, which has a rustic, natural appearance and is often made from recycled fibers; coated paper, which offers a glossy finish and is great for vibrant, full-color printing; and recycled paper, which is ideal for businesses committed to sustainability. The material you choose will depend on the type of look and feel you want, as well as the weight and durability requirements for the items you are packaging.

10. Can custom paper bags handle heavy products?

Yes, custom paper bags can be designed to handle heavier products. To ensure your bags can safely carry heavy items, we use thicker paper, reinforced handles, or even double-layered construction for extra durability. Bags made from heavy-duty kraft paper or with added reinforcements will be capable of holding more weight without tearing or breaking. If you’re planning to pack heavy or bulky items, it’s important to discuss these requirements with us to make sure the bags you order are suitable for your products.

11. How do I choose the right size for custom paper bags from a Laku Prosper Edge?

Choosing the right size for your custom paper bags depends on the products you intend to package. Start by measuring the dimensions of your products (height, width, and depth) and add some space for ease of packing. We can help guide you in selecting the right size based on your needs. Custom-sized bags are also an option, which ensures a perfect fit for your products. If you’re unsure, we provide size guides and samples, allowing you to test different bag sizes before placing a large order.

12. Are there any design limitations for custom paper bags from a Laku Prosper Edge?

While custom paper bags offer a lot of design flexibility, there may be a few limitations. For example, certain printing techniques may not be suitable for very detailed or fine artwork. Additionally, the size of the bag can influence the level of detail that can be printed, as smaller bags may not be able to accommodate intricate designs. Materials like kraft paper may also have a more rustic finish, which might not be ideal for some high-end, glossy designs. However, we will work with you to adjust the design to make sure it looks great within the constraints of the material and printing method.

13. How do custom paper bags help with branding and marketing?

Custom paper bags are a powerful tool for branding and marketing because they turn your packaging into a portable advertisement. Every time a customer carries your bag, they are effectively promoting your business. Custom bags with unique designs and your logo can capture attention in public spaces, increasing brand recognition. Additionally, they can enhance the perceived value of your products, especially if you’re offering premium or luxury goods. By choosing a design that reflects your brand’s personality, you can create a memorable and professional image for your business.

14. Are custom paper bags waterproof or water-resistant?

Custom paper bags are generally not fully waterproof, but they can be treated to be water-resistant. We offer the option of applying a coating, such as a water-resistant finish or lamination, which provides extra protection against moisture. This is particularly useful for businesses that want to ensure their bags hold up in damp or rainy conditions, especially for outdoor events or markets. However, if your bags need to be completely waterproof, you may need to explore alternatives or work with us to find a solution that works for your needs.

15. Can I add special features to my custom paper bags, like embossing or foil stamping, with a Laku Prosper Edge?

Yes, we offer special finishing options to elevate the look and feel of your packaging. Popular features include embossing, which creates a raised effect of your logo or design, and foil stamping, which adds a shiny metallic finish to your graphics. These special touches can make your custom paper bags look more premium and luxurious, making them perfect for high-end retail products, gifts, or special events. Be sure to discuss your design ideas with us to ensure that the techniques you want are possible with the materials and printing methods you’ve chosen.